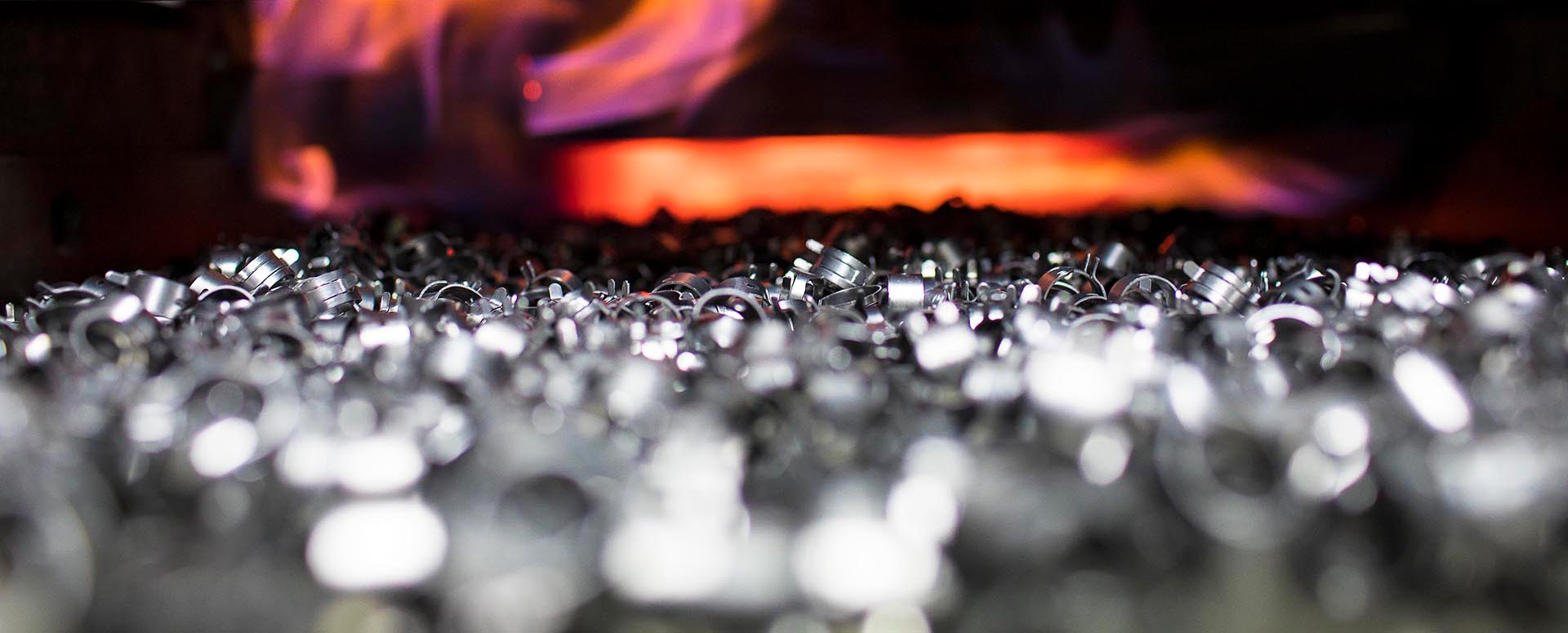

Hardening

In order to be able to process materials such as spring steel optimally, we fall back on heat treatment in our manufacturing processes through so-called austempering (tempering). As a service-provider, this process offers us a high level of process certainty and flexibility. It’s a major competitive advantage compared with conventional hardening processes.

The advantages of this type of heat treatment enable us at Vogt to produce customer-specific series products as well as prototypes quickly and economically. The additional advantages of the end-product, such as minimising the hardness distortion and the best-possible robustness with a high level of hardness, provide a broad spectrum of application options.

The process of austempering can be found for example in:

-

Seatbelt coverings

-

Anti-friction bearing components

-

Engines and gear parts, axles, drive shafts

-

Components in heavy-duty fuel injection pumps

The area of application generally includes components, which are made from a sheet of metal or a band with a small cross-section. Austempering is above all ideal for thin-cut components made of carbon steel because extraordinary weight-bearing capacity is required here. However: Not all components are suitable for hardening by austempering.

The advantages and positive features can be achieved only if no other structures are created during cooling, e.g. ferrite, perlite, upper bainite. There is therefore a range of components, which are typically used for this version of hardening.

Hardening in a salt bath

While the increase in hardness is achieved through martensite formation with normal hardening, with austempering it is an isothermal micro-structural transformation in the bainite stage, which occurs at a fixed temperature.

The component is first austenitised, this means heat treatment takes place at temperatures of 800 – 1,050°C regardless of the material. This process also occurs with conventional hardening. However, the subsequent quenching process is then captured in the austenitisation temperature, in other words above the martensite formation temperature. In general a salt bath with a temperature of approx. 300 – 400°C is selected for this.

Brief summary of the process:

-

Heating-up to the austenitising temperature

-

Maintaining the temperature

-

Quenching in the warm salt bath

-

Maintaining in the warm bath until the micro-structural transformation has been completed

Bainite structures will occur as the end-product of this process. These structures display specific characteristics compared with structures occurring with conventional hardening.

In detail these include:

-

Substantially lower hardness distortion of the parts

-

Longer life with high values

-

Smooth surface (no oxidation residues)

-

Very good combination of hardness and robustness